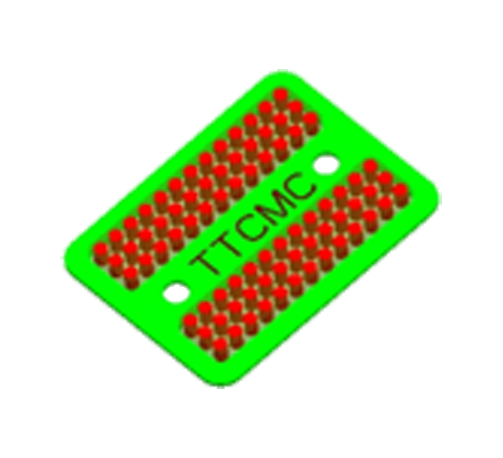

PRODUCT

CONDUCTIVE RUBBER : SIGNAL AND CURRENT TRANSMISSION

PCR conductive rubber is widely used in semiconductor packaging testing. It is commonly employed as part of test fixtures to ensure the reliability and performance of semiconductor components. Its primary applications include:

1. Test contact points: PCR conductive rubber is utilized to establish reliable electrical contact between semiconductor components and testing equipment, ensuring accurate signal transmission.

2. Damage prevention: During semiconductor packaging testing, PCR rubber serves as a cushioning material, preventing components from mechanical damage during testing.

3. High-frequency testing: For semiconductor components requiring high-frequency testing, PCR conductive rubber can provide excellent high-frequency performance, ensuring the accuracy of tests.

4. Noise reduction: PCR rubber effectively reduces noise generated during testing, aiding in ensuring the accuracy of test results.

In summary, PCR conductive rubber plays a crucial role in semiconductor packaging testing, helping to ensure the quality and performance of components.

PCR Production Process Specifications

Our company takes pride in our PCR conductive rubber products, which not only boast superior performance but also excel in process control rigor and reliability.

Our process control is rigorous, starting from the selection of raw materials, ensuring high-quality rubber substrates through strict inspection procedures.

In terms of conductivity performance, we employ the highest specification conductive balls, coupled with precise mixing processes, to ensure the even distribution of conductive ball particles within the rubber substrate, thereby reducing internal resistance values and achieving excellent electrical conductivity. Strict control during the process ensures product consistency, meeting customers' stringent requirements for quality, whether in terms of resistance values or durability.

| Test type | QFN BGA PCB FPC | ||

| Spacing | ≧ 0.35mm | High | 0.3mm ~ 2.0mm |

| Load | 15g ~ 50g | Bandwidth | 23 GHz @ -1dB |

| Test environment | -40℃ ~ +150℃ | Current | ≦ 1Amp |

| Compression stroke | 0.1mm ~ 0.25mm | Impedance | <100mΩ |

| Test life | 5k ~ 80k | ||